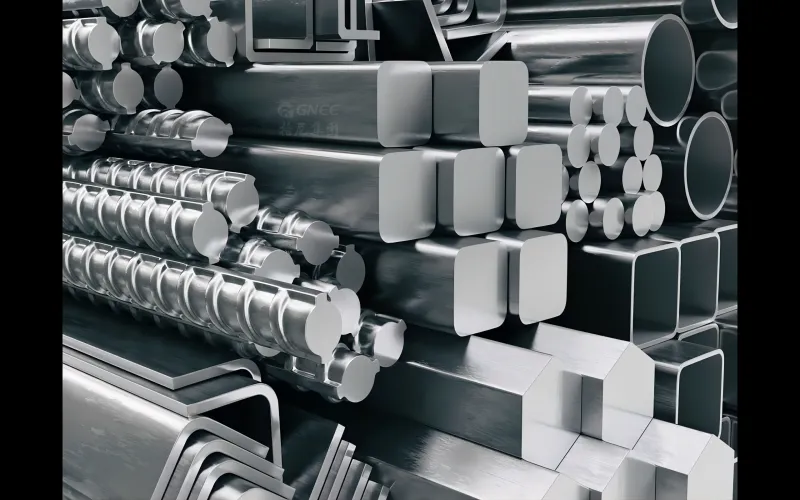

Trend 1 For Stainless Steel Pipe Development in China in the Future

Developing novel materials to adapt to many conditions and satisfying the demands of diverse industries are unavoidable prerequisites for the advancement of stainless steel pipes.

Designing target materials is an inevitable trend in the development of stainless steel pipes, given the use environment. Examples of this include designing pipes for high-oxygen water environments, creating pipes with radiation and pitting corrosion resistance, and designing pipes for seawater environments to achieve resistance to stress corrosion cracking and pitting corrosion. Additionally, designing pipes with resistance to high-temperature steam oxidation results in the creation of stainless steel pipes with various properties, including high strength, high plasticity, high toughness, high corrosion resistance, and high purity.

The national science and technology plan states that the following problems are primarily solved by it: antibacterial environments like biocompatibility; harsh environments like exhaust gas treatment; high-temperature environments like ultra-supercritical; high-pressure and high-corrosion environments for oil and gas development; and special environments like the transportation and processing of dangerous goods. Future developments of stainless steel pipes will need to address a variety of performance and high purity criteria, as well as the need to manufacture steel types from the source to suit diverse settings. excellent purity, high toughness, and great corrosion resistance.

Trend 1 For Stainless Steel Pipe Development in China in the Future

The development of stainless steel pipes revolves around three primary themes: energy saving, emission reduction, and innovative technology to create green businesses and green products.

Research, development, mass manufacturing, and commercialization of new technologies, including novel or already-existing items, are collectively referred to as process innovation. Significant process breakthroughs have the potential to cause major changes in an industry’s economic structure. Some underdeveloped trends include the ability of cold extrusion rolling technology to create significant deformation and enhance yield rate, eliminate the need for rolling oil during the rolling process, save more than 50% of electricity, and reduce the number of pickling passes. The product performs better than those made with the existing rolling and drawing processes. It may accomplish constant longitudinal and transverse tensile characteristics as well as the desired grain size following the user’s product specifications.

An essential component of application design is consistent performance both longitudinally and transversely. Tensile strength and transverse compression are the two principal uses for steel pipes. When choosing design materials, the thickness of the steel pipe will be chosen based on the minimal value when there is an anomaly in the longitudinal and transverse strength. It will be adequate when the longitudinal and transverse orientations are in harmony. Reducing the consumption resulting from diverse differences is a significant contribution to the development of a green and energy-efficient society as a whole, in addition to the business.

Trend 3 For Stainless Steel Pipe Development in China in the Future

Platforms for management innovation include “computer process-aided design,” “intelligent safety management,” “process intelligent service platform,” and “digital intelligent factory.” These platforms use computer simulation technology to realize the cold working plastic deformation control process, increasing the performance of the product.

Furthermore, the organization has advanced its production safety, employee pay, physical product quality, and production cost management through intelligent management. This will make it possible for domestic stainless steel pipe enterprises to progressively transition into an intelligent era marked by unmanned factories, intelligent quality control, intelligent process management, zero casualties, and timely delivery of goods.

Trend 4 For Stainless Steel Pipe Development in China in the Future

Zero emissions of waste liquid, wastewater, solid waste, and NO2 exhaust gas generated by the pickling process of stainless steel pipes are an unavoidable trend in future development in an era of increasingly strict national and local environmental protection policies. These days, the advancement of technologies like extreme crystallization, membrane technology, electrodialysis, and microfiltration makes it technically possible to treat the surface of stainless steel pipes with zero emissions.

In addition, implementing zero-emission technology in the production of stainless steel pipes offers social advantages in addition to being a straightforward way to guarantee environmental protection regulations. The economic benefits of recycling and reusing waste liquid, wastewater, and sludge can lower production costs for stainless steel pipe producers. The expenses are quite economically justified.

Trend 5 For Stainless Steel Pipe Development in China in the Future

Enterprise product processing extends along a chain that moves forward and backward in tandem with demand.

For instance, a technology business in Foshan manufactures large-scale ferrite (445J2) reduction tubes. One piece is used for each air conditioner, and it begins with extension processing.

Another illustration would be that some metal fabrication businesses focus on producing small-diameter, thin-walled coils with pipe diameters greater than 6mm, wall thicknesses greater than 0.4mm, and single lengths of several thousand meters. Each year, thousands of tonnes of them are utilized for signal and heat exchanger tubes.

Additionally, a company in Taiyuan manufactures very precise small-diameter special-shaped pipes with a high added value for use in high-end national defense equipment.

The future of the stainless steel pipe industry is, in brief, supply-side reform, green development, and inventive development.