What Are Austenitic Stainless Steels?

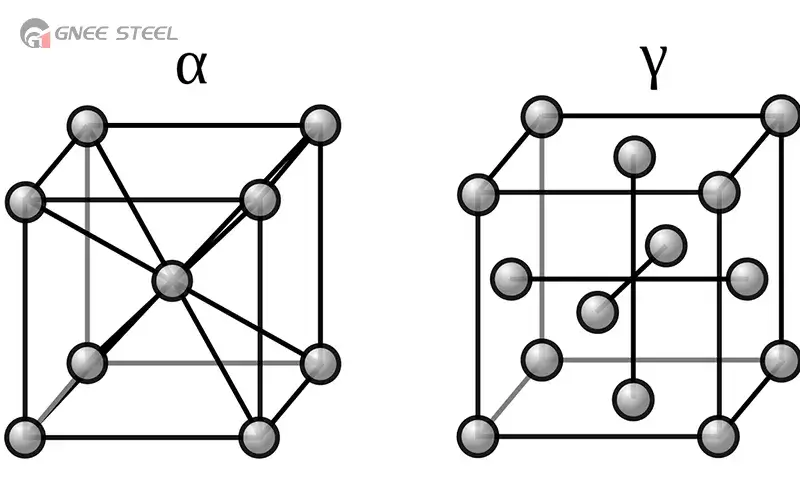

Austenitic stainless steel is a common type of stainless steel that gets its name from the type of crystal structure that is predominantly present in it, austenitic. The austenitic crystal structure is a face-centered cubic structure with high stability and corrosion resistance. Austenitic stainless steel refers to stainless steel with an austenitic structure at room temperature. When the steel contains about 18% Cr, about 8%~25% Ni, and about 0.1% C, it has a stable austenite structure. Austenitic stainless steel is non-magnetic and has high toughness and plasticity, but its strength is slightly low, and it is impossible to strengthen it through phase transformation. It can only be strengthened by cold working, such as adding elements such as S, Ca, Se, and Te. This stainless steel is widely used in a variety of applications due to its excellent corrosion resistance and mechanical strength. Most of the common 300 series stainless steel coils such as 301 and 304 are austenitic stainless steel.

What Is Ferritic Stainless Steel?

Ferritic stainless steel is a type of stainless steel that gets its name from the type of crystal structure found predominantly in it, known as ferrite. The ferritic crystal structure is a body-centered cubic structure with high strength and hardness, which is excellent in mechanical applications. Ferritic stainless steel usually contains a certain proportion of chromium (Cr) and low or no nickel (Ni). The chromium content is 15%~30%, and sometimes contains a small amount of Mo, Ti, Nb, and other elements. balance between. Ferritic stainless steel has the characteristics of large thermal conductivity, small expansion coefficient, good oxidation resistance, and excellent stress corrosion resistance. At the same time, the price is relatively low and stable, and it is widely used in various applications. Common 400 series stainless steel coils such as 409, 410, 420, etc. are generally ferritic stainless steel.

Difference Between Austenitic and Ferritic Stainless Steel

- Austenitic steel is a stainless steel containing at least 10% chromium and 8% nickel.

- Ferritic steel is a type of stainless steel that contains less than 10% chromium.

- Austenitic steels are non-magnetic, while ferritic steels are magnetic.

- Austenitic steels are more ductile and easier to weld than ferritic steels.

- Austenitic steels are more corrosion-resistant than ferritic steels.

- Better prices for ferritic steels.

Both stainless steels have excellent properties, but depending on their environment, one may be more advantageous than the other for certain applications. For example, if you need a material with higher heat resistance, then austenite is better, while if you need a material with higher ductility, then ferrite will be a better choice.

Duplex Stainless Steel Coil

Austenite and ferrite are two different crystal structures with different properties. Austenite has higher corrosion resistance, while ferrite has higher mechanical strength. By adjusting the composition of alloying elements, duplex stainless steels achieve a balance of these two phases, resulting in a compromise between corrosion and strength, with excellent properties in many applications.

The chloride pitting and crevice corrosion resistance of duplex stainless steel is related to the content of chromium, molybdenum, tungsten, and nitrogen, which can be similar to or higher than that of 316 stainless steel. All duplex stainless steels are significantly more resistant to chloride stress corrosion cracking than the 300 series austenitic stainless steels and are much stronger than austenitic stainless steels while exhibiting good plasticity and toughness.

Duplex Stainless Steel for Sale

2205 Duplex Stainless Steel Coil

2205 Stainless Steel Coil is a duplex stainless steel material with excellent corrosion resistance, strength, and toughness. Widely used in chemical industry, marine, energy and construction, and other fields. Compared with some other stainless steel materials, 2205 stainless steel coils are superior in corrosion resistance, strength, and welding performance.

Duplex 2507 Stainless Steel Coil

2507 stainless steel coil refers to the stainless steel coil made of 2507 duplex stainless steel, also known as SAF 2507. This stainless steel is a combination of austenitic and ferritic stainless steels with high levels of chromium, molybdenum, and nitrogen. Due to the duplex structure, the 2507 stainless steel coil has more advantages than other types of stainless steel. Commonly used in oil, gas, chemical processing, pulp production, and other industries requiring high corrosion resistance and mechanical strength.

What Are the Characteristics of Duplex Stainless Steel Coil?

- Good corrosion Resistance: able to resist a variety of corrosive media, including acid, alkali, salt, etc. At the same time, it can resist stress corrosion cracking and intergranular corrosion and is suitable for use in harsh environments.

- Excellent Mechanical Properties: It has high yield strength, tensile strength, and impact toughness, and can maintain good mechanical properties under high and low-temperature conditions.

- Excellent Welding Performance: It can be welded without affecting the properties of the material.

- Excellent Processing Performance: With good plasticity and forgeability, it is easy to process into products of various shapes and sizes, and is suitable for complex processing techniques.

Application of Duplex Stainless Steel Coil

Chemical Industry: such as reaction kettles, storage tanks, pipelines, heat exchangers, etc. in chemical equipment.

Food Processing: such as food conveyor belts, food storage tanks, food processing equipment, etc. in food processing plants.

Energy Industry: such as natural gas pipelines, storage tanks, oil extraction equipment, etc.

Ocean Engineering: such as manufacturing offshore platforms, submarine pipelines, ships, seawater desalination plants, high-pressure reverse osmosis equipment, etc.

Medical Industry: such as surgical instruments, implants, etc.

Architecture and Structure Fields: such as building facades, roofs, bridges, and other structures.

Papermaking and Fiber Industry: It can be applied to various equipment in the process of papermaking and fiber production, such as steam generators, storage tanks, conveyors, etc.

High-Quality Duplex Stainless Steel Coils Supplier

The Gnee Steel Group is a professional supply chain enterprise, mainly engaged in steel plate, coil, profile, and outdoor landscape design and processing. After 15 years of development, it has become a leading international steel supply chain company in the Central Plains. Relying on many iron and steel enterprises such as Angang Steel, we have a wide variety of products, including shipbuilding plates, pressure vessel plates, bridge decks, etc. We also provide pipes, bars, engineering design and manufacturing, and comprehensive stainless steel solution services. Cooperating with more than 600 companies around the world, the annual export capacity exceeds 80,000 metric tons. Choose Gnee Steel Group, you choose a professional and reliable steel supply chain partner!