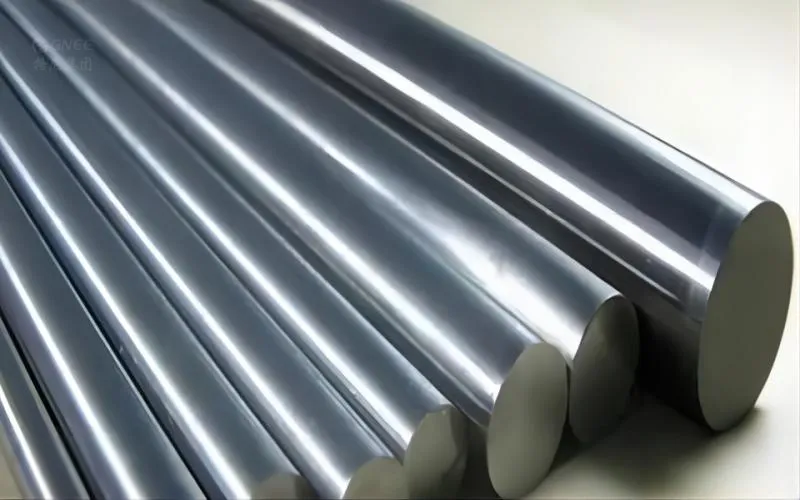

What Is a Stainless Steel Round Bar?

A kind of metal bar with a round cross-section that is composed of stainless steel is called a stainless round bar. It is frequently utilized for a variety of purposes in the industrial, engineering, construction, and other industries. Stainless steel is preferred because of its resistance to corrosion, strength, and visual attractiveness.

To meet the needs of diverse projects, stainless steel round bars are available in a range of diameters and lengths. They are frequently employed in the production of fastener parts like bolts, nuts, and screws. Although the exact grade of stainless steel used can vary, Grade 304 is frequently chosen due to its resistance to corrosion and adaptability.

Round stainless steel bars are available from several vendors and websites that focus on selling metal rods and bars. It’s crucial to take your project’s particular specifications into account when choosing a stainless round bar, including the diameter, length, and quality of stainless steel required.

What Is 303 Stainless Steel Round Bar?

One kind of stainless steel bar composed of grade 303 stainless steel is called the 303 Stainless Steel Round Bar. It is frequently used for applications requiring strong machinability and corrosion resistance in a variety of industries.

Sulfur and selenium are added to Grade 303, an austenitic stainless steel that is free-machining and has improved machinability. It is renowned for having moderate strength, strong corrosion resistance, and great machinability.

How to Distinguish the Difference Between a 304 Stainless Steel Round Bar and a 303?

- Examine the superficial analogy

Sulfur-containing substance 303 has a bright surface but a somewhat dark overall appearance. In comparison to 304, there is a slight decrease in brightness. 304 appears to have a bright, smooth surface.

- Evaluation of processing capabilities

Sulfur-containing substance 303 offers higher turning performance and is easier to process. It works well with automatic lathes. Typically, stock diameters range from 5 to 65 millimetres. High-strength alloy steel is found in material 304. In addition, it has resistance to creep, high temperatures, and pitting corrosion. It is appropriate for the pipeline, food, and medical industries.

- Comparison of material tests

The materials 303 and 304 are from the same series, and their approximate contents are also the same. Only 304 with a high sulphur concentration is used to make 303. You could test the substance.

- A comparison of the manufacturer’s material certification

Because the components of 303 and 304 are different, we can ask the manufacturer to give material certification when we need to buy 304 stainless steel round bar supplies. This comparison allows us to choose the appropriate material.

Characteristics of 303 Stainless Steel Round Bar

1. Easy to process: 303 stainless steel is frequently referred to as “processed stainless steel” because of its excellent processing capabilities, particularly its ease of cutting.

2. Good corrosion resistance: 303 stainless steel round bars can be utilized in locations where a high level of corrosion resistance is required because of their good corrosion resistance.

3. Good heat resistance: 303 stainless steel round bars are still capable of performing well in hot conditions and can be employed in hot environment applications.

4. Great mechanical properties: It can be utilized in applications that call for high strength and wear resistance because of its great strength and wear resistance.

5. Easy to clean: 303 stainless steel round bars are easy to clean because of their smooth surface and lack of dust retention.

How 303 Stainless Steel Round Bars Be Used For?

1. Machined Components: 303 stainless steel round bars are highly machine-able and are frequently used in the production of machine-made parts including nuts, bolts, screws, and fittings.

2. Aerospace sector: For applications requiring high strength, resistance to corrosion, and superior machinability, the aerospace sector uses round bars made of 303 stainless steel. Landing gear, structural pieces, and aircraft components can all be made with these bars.

3. Automotive Sector: 303 stainless steel round bars are used in the automotive sector to make engine parts, exhaust systems, fasteners, and fittings, among other components.

4. Food Processing Equipment: 303 stainless steel can be used in food processing equipment because of its corrosion resistance. Parts for food handling machinery, mixing apparatus, and conveyor systems are frequently made with it.

5. Medical gadgets: The manufacturing of medical equipment and gadgets uses 303 stainless steel round bars. Their corrosion resistance and biocompatibility make them useful in the production of dental tools, implants, and surgical instruments.

6. Marine Applications: 303 stainless steel round bars are used in the marine industry for applications where corrosion resistance in seawater settings is a requirement. The production of naval hardware, fittings, and components can employ these bars.