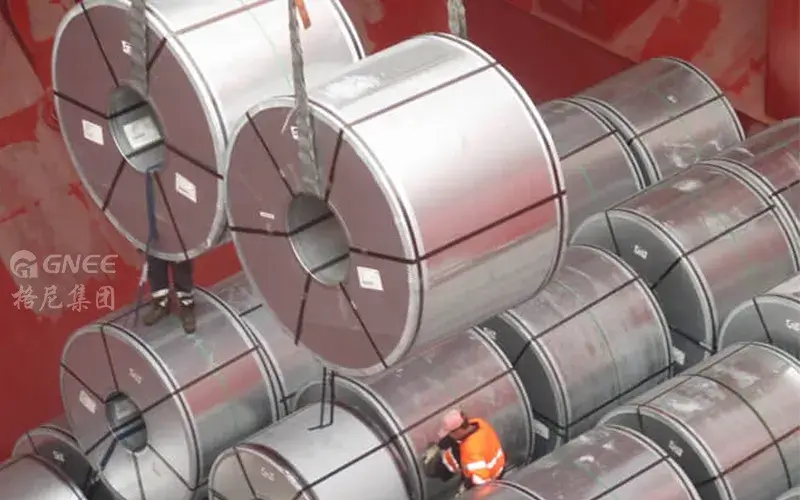

Into The Stainless Steel Coil !

Stainless steel coils are rolled stainless steel flat sheets into cylindrical shapes and are manufactured from a range of stainless steel alloys. With excellent durability, corrosion resistance, easy processing, easy transportation, multi-functionality, and many other excellent properties, it is the basic component of various industries and is widely used in aerospace, automotive, construction, chemical processing plants, food manufacturing, medical equipment production, and other fields.

What Is 321 Stainless Steel Equivalent to?

Properties of 321 Stainless Steel

In the field of stainless steel coils, type 321 stands out due to its special composition and excellent properties.

The high chromium content (17-19%) ensures that the material remains resistant to fouling even in high-temperature environments. When exposed to oxygen, moisture, and other environments, the presence of a large amount of chromium will form an oxidative film on the surface of the stainless steel coil, making the stainless steel not easy to rust and lose luster.

A distinctive feature of 321 stainless steel coils is the addition of titanium as a stabilizing element. Helps prevent intergranular corrosion that may occur during exposure to high temperatures or during soldering. By bonding to the carbon atoms in the material’s structure, titanium forms stable carbides that prevent sensitization. Additionally, this addition enhances weldability by reducing the potential for brittleness during manufacturing processes such as welding and forming.

Additionally, the nickel content (9-12%) contributes to overall robustness and increases resistance to acids and alkalis.

Application of 321 Stainless Steel Coil

The versatility of 321 Stainless Steel Coil extends to a wide range of industries, and its exceptional properties make it a valuable material choice. An important field of use of this alloy is the aerospace industry. In this field, 321 stainless steel coils can be applied in exhaust systems, jet engine parts, heat exchangers, etc.

Another industry that benefits from the advantageous properties of Type 321 stainless steel coil is chemical processing. In this field, furnace equipment, refining equipment, storage tanks, etc. usually require materials that can prevent corrosion from acidic and other chemical environments while maintaining structural integrity. Therefore, the corrosion resistance and stability of 321 stainless steel coils make it It has become an ideal choice for the chemical industry.

Is 321 Stainless better than 316?

Whether 321 stainless steel is better than 316 stainless steel depends on the specific application and application needs. Both are relatively high-quality materials with their unique properties and characteristics.

1. Corrosion Resistance:

316 stainless steel contains molybdenum, which enhances its resistance to pitting and crevice corrosion. Known for its excellent corrosion resistance, especially in marine and chloride-rich environments.

Contains titanium, which is a stabilizing material against sensitization during welding, thereby reducing the risk of corrosion in certain applications.

2. Temperature Resistance:

When the equipment needs to work in a high-temperature environment, the choice of stainless steel becomes very important. In high-temperature resistance, there is a clear difference between 316 and 321. 316 stainless steel is excellent at moderately high temperatures but is not as resistant to high temperatures as 321 stainless steel.

3. Weldability:

321 stainless steel, while weldable, requires extra care when welding due to its titanium content. Post-weld heat treatment is generally recommended to maintain corrosion resistance. In comparison, 316 stainless steel is easier to weld.

What Is the Difference between 304 and 321 Stainless Steel?

When we talk about stainless steel, it’s easy to get confused by the numbers and terminology. But don’t worry, today we are going to explore the differences between the two stainless steels, 304 and 321, in a light-hearted manner. Helps you better understand how they work in different applications.

304 stainless steel coils are a classic choice. It has a famous name called “18-8 stainless steel” because it contains 18% chromium and 8% nickel. With excellent corrosion resistance, it is suitable for various scenes, such as kitchen utensils, construction and decoration, etc.

321 stainless steel coils are somewhat similar to 304, but also somewhat different. It also contains 18% chromium and 8% nickel, but also has a special ingredient: titanium (usually between 0.70% and 1.0%). This little titanium makes the 321 a “superhero” in the high-temperature field.

321 stainless steel performs better at high temperatures and is less susceptible to heat sensitization. If your equipment needs to work in high-temperature environments, such as furnaces, engine exhaust systems, or aircraft parts, then 321 is your best choice.

But, having said that, 321 requires extra care when soldering. Some special treatment is usually required after welding to ensure that its corrosion resistance is not affected.

Find the Right Stainless Steel Coil Supplier

When you are looking for an excellent stainless steel coil supplier, you often need to consider multiple factors. Only by choosing a suitable stainless steel coil supplier can you get high-quality products that meet your needs and establish a long-term and reliable cooperative relationship.

Quality Assurance: Ensure compliance with industry standards

First, you need to make sure the supplier promises quality assurance. A trusted supplier should adhere to industry standards and have strict quality control processes. You can look for suppliers with relevant certifications such as ISO certification, ASME certification, PED certification, etc., which show their strength.

Product Range and Availability: Extensive selection, well-stocked

Second, the supplier’s product range and stock availability are also key factors. A reliable supplier should offer a variety of stainless steel coil types, sizes, grades, and surface treatment options to meet the needs of different customers. In addition, sufficient inventory should also be maintained to ensure timely delivery without compromising product lead times.

Customer Service: Responsiveness, technical support, after-sales service

When evaluating suppliers, consider their responsiveness to your inquiries or concerns. Also, consider whether they have efficient after-sales service in dealing with issues that may arise after purchase.

Market Reputation: Customer reviews, industry reputation, long-term cooperative relationship

Finally, don’t forget to research the vendor’s market reputation. Check out customer reviews and testimonials for their past performance and customer satisfaction. Also, consider their reputation within the industry, including track record, history of business operations, and any achievements or recognitions they may have received.

China Stainless Steel Coil Suppliers

Gnee Steel Group is a professional supply chain enterprise, mainly engaged in the processing of steel plates, coils, profiles, and outdoor landscape design. After 15 years of development, it has become a leading international steel supply chain company in the Central Plains. Relying on Angang and other iron and steel enterprises, we have a wide variety of products, including shipbuilding plates, pressure vessel plates, bridge decks, etc. At the same time, we provide pipes, bars, engineering design and manufacturing, and comprehensive stainless steel solution services. Cooperating with more than 600 companies around the world, the annual export capacity exceeds 80,000 metric tons. Choose Gurney Steel Group, you choose a professional and reliable steel supply chain partner!