Difference Between Stamped and Embossed Stainless Steel Plate

While both techniques bestow upon the stainless steel surface a certain degree of embellishment, they make a difference in many aspects, including their definition, manufacturing process, pattern variations, durability, applications, cost, etc. Continue to see more below.

1. Definition

Stamped stainless steel plate is a type of sheet that has undergone a stamping process to create various shapes, patterns, or designs on its surface.

Embossed stainless steel plate is a type of sheet that has undergone an embossing process to create various shapes, patterns, or designs on its surface.

2. Manufacturing Process

One main difference between stamped stainless steel plates and embossed stainless steel plates lies in their manufacturing process. The former often uses the stainless steel plate as the substrate, and the latter uses the stainless steel coil as the base metal. And their manufacturing processes are also different. For example:

Embossing Process: it is produced by rolling the stainless steel coil straight into the embossing mold to form designs on the coil surface. Then the coils will be sliced into plates. Usually, embossed stainless steel plate has a raised design on one side and the other is flat.

Stamping Process: it is produced by passing stainless steel plates through a series of rollers, each side of the roller with a different pattern. This process aims to create raised designs on both sides of the stainless steel plate. Usually, stamped stainless steel plate has concave patterns on one side and convex patterns on the other side.

3. Thickness

Embossing requires less pressure and can be used on thinner metals, while stamping requires more pressure and can be used on thicker metals.

Therefore, embossed stainless steel sheets often use base metal with a thickness of around 2mm while the thickness of stamped stainless steel substrate may be up to 3mm thick.

4. Patterns

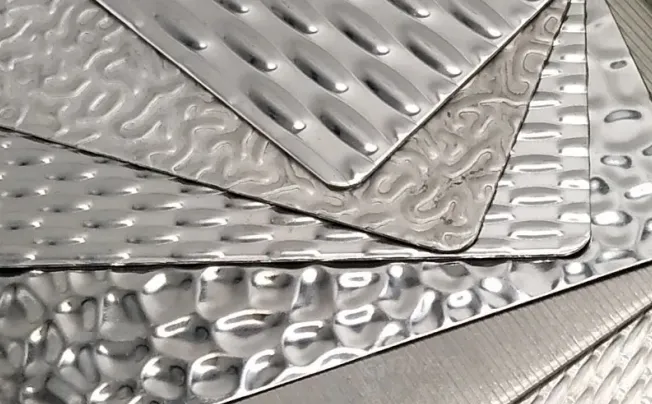

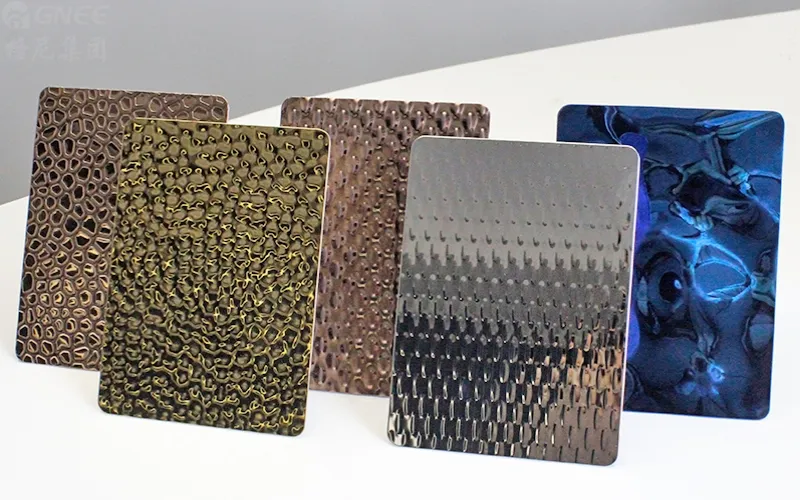

When it comes to pattern options, stamped stainless steel plate offers a vast array of possibilities. The art of stamping allows for the creation of more intricate, sharper, and finer designs, including logos, text, and custom patterns.

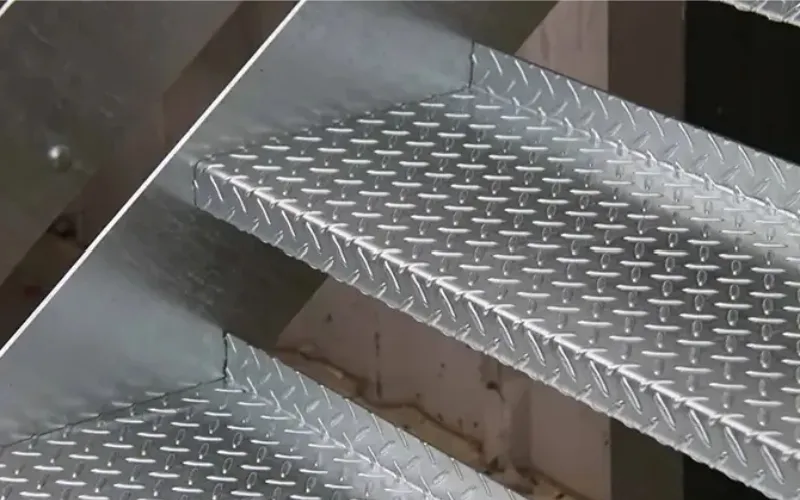

On the other hand, embossed stainless steel plates offer more textured and three-dimensional patterns that can enhance the plate’s aesthetic appeal. Common embossed designs include geometric patterns, diamond patterns, T-shaped patterns, round bean patterns, lentil patterns, bar-shaped patterns, etc.

In addition, it should be noted that the patterns of stamped stainless steel plates are less flat than those of embossed stainless steel plates.

5. Durability

Both stamped and embossed stainless steel plates are renowned for their durability and longevity.

6. Common Properties

Both stamped and embossed stainless steel plates can be made of 304, 304L, 316, or 321 stainless steel, so they have the same common properties.

7. Formability

Both stamped and embossed stainless steel plates can be cut, bent, formed, and welded.

8. Maintenance

The raised surface of the metal provides a level of protection against wear and tear, making it ideal for high-traffic areas. Therefore, they are both easy to clean and maintain.

9. Applications

Stamped stainless steel plates present a more prominent, elevated, and defined pattern. Therefore, they are frequently employed for decorative purposes. Some typical examples include retail fixtures, displays, furniture, jewelry, and sculptures.

In contrast, embossed stainless steel plates exhibit a textured pattern that is commonly utilized for functional intentions, such as providing a grip or mitigating glare. Some of the notable applications are stair treads, elevator panels, garage door panels, metal office furniture, automotive trim, and building products.

In a word, the choice between stamped and embossed plates ultimately hinges upon the desired aesthetic and functional requisites.

10. Cost

Stamped stainless steel plates, owing to their intricate detailing and precise manufacturing process, tend to be more expensive.

Conversely, embossed stainless steel plates offer a relatively more cost-effective alternative. The embossing process, being less intricate and requiring less labor, results in lower production costs. Furthermore, embossed plates can be produced in larger quantities at a lower cost per unit, making them an economically prudent choice for discerning individuals.

Stamped Vs. Embossed Stainless Steel Plate, Which one to Buy?

When deliberating between stamped and embossed stainless steel plates, several factors should be taken into consideration.

Firstly, one must assess the intended use and purpose of the plates. If the primary aim is to enhance visual appeal, stamped plates may be the preferred option. However, if functionality and practicality hold greater importance, embossed plates may prove more advantageous. Additionally, one must take into account the environment in which the plates will be installed. Elements such as exposure to moisture, fluctuations in temperature, and cleaning requirements can influence the durability and upkeep of the plates.

Thirdly, material thickness, sheet size, and pattern styles must be taken into account.

Lastly, financial limitations and personal preferences should also be taken into consideration when making a decision.

Conclusion

Here at Gnee, we specialize in the production of high-quality patterned stainless steel plates, including stamping stainless steel plates and embossed stainless steel plates. Due to our more than 15 years of experience in production, we ensure that we have the best quality and offer the best advice for the design of your projects. Contact us today to learn more about this unique and versatile product or get free samples!