Stainless Steel Plate: Hot Rolled vs. Cold Rolled

Hot rolling and cold rolling are two different manufacturing processes used to produce stainless steel plates. Each process possesses its unique characteristics and key features that render it suitable for diverse applications. By comparison, here are the key differences between hot rolled stainless steel plates and cold rolled stainless steel plates.

1. Definition

Hot rolled stainless steel plate is a type of steel created by subjecting a stainless steel slab to elevated temperatures and rolling it into the desired thickness.

Cold rolled stainless steel plate is a type of steel created by subjecting hot rolled stainless steel plates to additional cold rolling and annealing processes.

2. Manufacturing Process

The main difference between hot rolled stainless steel plate and cold rolled stainless steel plate lies in the manufacturing process: the former is hot rolling, and the latter is cold rolling.

Hot rolled stainless steel plate is made through hot rolling process. It is manufactured by heating a stainless steel slab above its recrystallization temperature and subsequently rolling it into the desired thickness.

Cold rolled stainless steel plate is made by cold rolling process. It is produced by further processing hot rolled stainless steel plates through a series of cold rolling and annealing steps at room temperature.

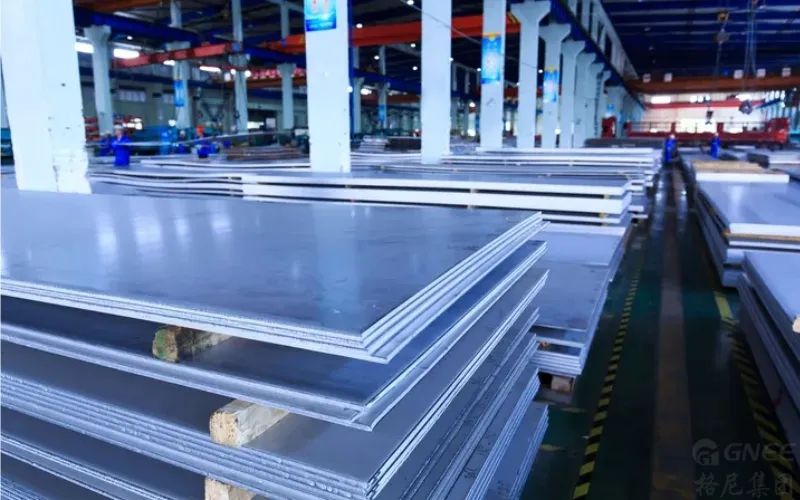

3. Appearance

After the manufacturing process is completed, we could find some differences in their appearance first.

HR stainless steel plate usually possesses a rough and scaled texture with slightly rounded edges. This texture is a consequence of the high temperature during the rolling process, which causes the steel to oxidize and form a layer of scale. As a result, hot-rolled stainless plates have a less smooth and polished appearance compared to their cold-rolled counterparts.

CR stainless steel plate presents a smoother and more polished texture compared to hot rolled one. The cold rolling process effectively removes the scale and impurities that are present on the surface of hot rolled stainless steel plates, resulting in a clean and refined appearance. Additionally, it exhibits superior flatness and straightness.

4. Corrosion Resistance

We could find that hot rolled stainless steel plate is more corrosion-resistant than cold rolled stainless steel plate. The additional processing of cold rolled stainless steel plate will cause some certain damage to the surface of the plate itself, thus decreasing the performance of preventing corrosion resistance.

5. Durability

Correspondingly, hot rolled stainless steel plate usually has a longer service life than cold rolled stainless steel plates.

6. Mechanical Properties

They present different mechanical properties, in terms of hardness, tensile strength, and formability.

Hardness: cold rolled stainless steel plate enhances their strength and hardness while maintaining their dimensional accuracy as it is produced by subjecting hot rolled stainless steel plates to further processing through cold reduction mills.

Tensile Strength: hot rolled stainless steel plate has higher tensile strength and yield strength than cold rolled counterparts due to the hot rolling process.

Formability: hot rolled stainless steel plates are highly regarded for their excellent formability, allowing them to be easily shaped, welded, and bent according to the requirements of different applications. Cold rolled plates may be less formable due to the additional processing steps involved.

7. Applications

Each type possesses its unique applications owing to their different properties.

Hot rolled stainless steel plates are commonly employed in applications that necessitate high strength, durability, and suitability for applications requiring robust performance. So they are widely used in the construction, automobile, manufacturing, machinery, and energy industries.

Cold rolled stainless steel plates are renowned for their smooth and polished appearance, making them suitable for applications that require an aesthetic appeal and precision engineering. They are more applied in household appliances, decorative items, precision engineering components, and elevators.

8. Cost

It is crucial to note that cold rolled stainless steel plate is generally more expensive than its hot rolled counterpart due to its extra processing.

Hot rolled stainless steel plate is generally more affordable due to its good formability and wide availability in various thicknesses and sizes.

Conclusion

In a word, understanding the differences between hot rolled stainless steel plates and cold rolled stainless steel plates is a very important step for those who often work with steel. That will greatly facilitate the smooth progress of their engineering projects related to steel. If you are choosing between cold rolled and hot rolled stainless steel plates, you can consider the above details or contact our technical team for help.