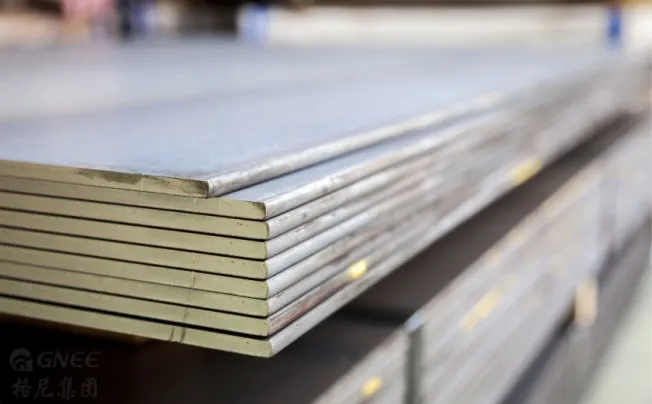

What Is Stainless Steel Medium-thickness Plate?

Stainless steel medium thickness plate is a versatile material with a moderate thickness, typically ranging from 3mm to 50mm. In addition, it is primarily composed of iron, chromium, and other alloying elements like nickel and molybdenum, which give it exceptional corrosion resistance, high strength, and durability. However, it is important to note that the precise composition of this plate may vary depending on the specific grade and the unique requirements of the intended application.

Properties of Stainless Steel Medium Thickness Plate

Stainless steel medium thickness plates offer several advantages, including:

1. Excellent Corrosion Resistance: stainless steel material is highly resistant to corrosion, making it suitable for various environments, including those with high moisture or chemical exposure.

2. High Strength and Great Durability: medium-thickness stainless steel plates provide excellent strength and durability, capable of withstanding heavy loads and harsh conditions.

3. Hygienic Properties: the metallic surface makes it easy to clean and maintain, making it suitable for applications where hygiene is crucial, such as in food processing and medical equipment.

4. Aesthetic Appeal: the plate has a sleek and modern look that can enhance the visual appeal of products and structures.

5. High-Temperature Resistance: it can withstand both high and low temperatures, making it versatile for use in different temperature environments.

6. Recyclability: stainless steel medium thickness plate is fully recyclable, making it an environmentally friendly material choice.

7. Fabrication Flexibility: it can be easily fabricated into different shapes, making it suitable for a wide range of applications in various industries.

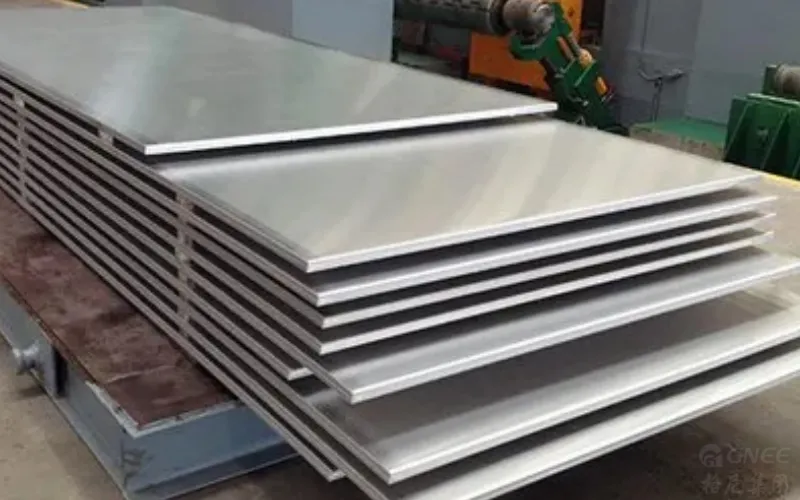

Overall, medium thickness stainless steel plates offer a combination of strength, longevity, and resistance to environmental factors, making them a preferred choice in many industrial and commercial applications.

Common Uses of Stainless Steel Medium Thickness Plate

Due to its exceptional properties, stainless steel medium-thickness plate is widely used in various industries.

In the construction and architectural sector, it finds itself indispensable for the creation of structural components, facades, and decorative elements.

It is also used in marine applications, including shipbuilding and the construction of offshore structures.

Furthermore, the chemical and petrochemical industry relies heavily on this plate for the construction of storage tanks, pipelines, and equipment that are exposed to corrosive substances.

Finally, its versatility extends to the realm of food processing equipment, automotive components, and industrial machinery, where strength, durability, and resistance to corrosion are of paramount importance.

Manufacturing Process of Stainless Steel Medium Thickness Plate

The manufacturing process of stainless steel medium thickness plate involves several steps, including the preparation and selection of raw materials, hot rolling and cold rolling techniques, heat treatment and annealing processes, and surface finishing and coating methods.

1. Raw Material Preparation and Selection

To produce stainless steel medium thickness plates that possess superior properties, it is imperative to commence the process with meticulous preparation and selection of the raw materials. The process commences with the acquisition of high-quality stainless steel alloys, which typically consist of a harmonious combination of iron, chromium, and other elements. These alloys are subjected to scrupulous analysis and testing to ensure that they meet the required chemical composition and mechanical properties. Once the most suitable alloys have been identified, they undergo rigorous cleaning and pre-treatment processes to eliminate any impurities and enhance their overall quality.

2. Hot Rolling and Cold Rolling Techniques

Proceeding to the subsequent stage of the manufacturing process, we encounter the utilization of hot rolling and cold rolling techniques. Hot rolling is executed at elevated temperatures, typically surpassing the recrystallization temperature of the stainless steel alloy. This intricate process involves passing the material through a series of rollers, thereby reducing its thickness and refining its mechanical properties. On the other hand, cold rolling is performed at ambient temperatures and further refines the material’s thickness and surface finish. These rolling techniques are instrumental in achieving the desired thickness and dimensional accuracy of the medium thickness plates.

3. Heat Treatment and Annealing Processes

The pivotal role played by heat treatment and annealing processes in enhancing the strength, hardness, and corrosion resistance of stainless steel medium thickness plates cannot be overstated. Heat treatment entails subjecting the plates to meticulously controlled heating and cooling cycles, thereby altering their microstructure and properties. Annealing, a specific heat treatment process, is conducted to relieve internal stresses and enhance the material’s ductility. These processes optimize the mechanical properties of the plates, rendering them suitable for a myriad of applications.

4. Surface Finishing and Coating Methods

Surface finishing and coating methods are employed to augment the appearance, corrosion resistance, and durability of stainless steel medium thickness plates. The plates undergo various surface treatments, such as pickling, passivation, and polishing, to eliminate impurities, oxide layers, and surface defects. Furthermore, protective coatings, such as electroplating or organic coatings, can be applied to provide an additional layer of safeguard against corrosion and wear. These meticulous surface finishing and coating methods ensure that the plates meet the required aesthetic and functional standards, leaving no room for compromise.

High-quality Stainless Steel Medium-thickness Plate for Sale

As a variant of stainless steel plate, stainless steel medium thickness plate not only inherits excellent corrosion resistance from stainless steel but also exhibits unparalleled mechanical properties due to its high thicknesses. This is why it is very suitable for many complex environmental applications, including construction sites, marine applications, mineral exploration, strongly corrosive environments, etc. If you are also interested, welcome to contact us. Gnee Steel provides premium stainless steel medium-thickness plates in 321, 347, 410, and 904L grades, ready for your next steel projects!