11 Steps to Drill Stainless Steel Plate

To drill stainless steel plates, there are several important steps and considerations to keep in mind. Here is a general guide on how to drill stainless steel plates by using a power drill as an example.

1. Select Your Drill Bit

When drilling into stainless steel plate, the key to success is selecting the right drill bit for the job. Although many different types of drill bits are suitable for drilling stainless steel on the market, going for the best will improve your chances of getting good results and ease the process. Here are two for your reference:

High-speed steel drill bit — This type of bit is designed for drilling high-tensile and heavy-duty performance metals. The best HSS drill bits to use for drilling stainless steel are those with a Titanium Nitride tip to help reduce friction and heat.

Cobalt drill bit — Cobalt drill bits are designed explicitly to work on stainless steel and will give you better results than standard twist or masonry bits. Cobalt can be used to increase the strength of the parent metal and boost its heat resistance properties, both of which are vital when drilling stainless steel plates. In addition, cobalt drill bits can last up to six times longer than standard high-speed steel bits but also cost more.

If you only have one or two holes to drill, a standard high-speed steel drill bit will be fine. For more holes, a cobalt drill bit is recommended.

2. Prepare Materials

With the right drill bits, other related preparations will be much easier. Before you get started, you need the following items:

Stainless steel plates.

Coolant or lubricant.

Protective gear like working gloves and eye protection goggles. Additionally, you should avoid any loose cloth that may be caught between the drills.

3. Secure Your Metal in Place

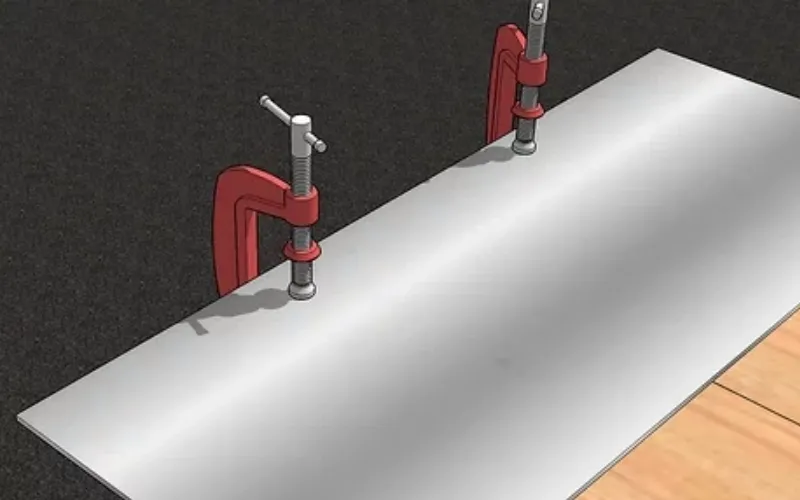

Trying to drill into a piece of stainless steel plate metal without securing it is a recipe for disaster. If the drill bit catches or vibrates during the drilling process, it could cause the metal to spin around violently, slashing at anything and anyone in the vicinity. Therefore, to ensure proper security, secure your metal in place well. Here’s how you can use clamps or fixtures effectively:

Use a Vise: if you’re drilling a small piece of stainless steel plate, consider using a vise to hold it securely in place. A vise provides stability and allows you to concentrate on the drilling without worrying about the workpiece moves.

Use a Clamp: for large stainless steel plates, use clamps to secure them to a workbench or a sturdy surface. Position the clamps strategically to prevent any obstruction to the drilling area and ensure a stable work environment. Below is a picture for your reference.

Use Supports: when drilling larger stainless steel sheets and plates, use a sacrificial backing material such as wood or plastic. This backing material prevents the stainless steel from flexing or getting damaged while drilling and provides support for precise holes.

Always remember not to put the stainless steel plate on your lap.

4. Mark Your Spot

Drill bits tend to wander when you first start drilling. To prevent this, measure and mark where you want the hole. Mark the intended hole location with a pen and then use a center punch ( use a nail if you don’t have a center punch) and hammer to create a small dimple. This will help keep the tip of your drill bit in place as you start to drill. This is especially important when drilling larger holes, as off-center drills can cause unnecessary wear and tear on both your bit and your metal.

5. Protect Yourself

Safety always comes first. As with any construction project, it’s important to take steps to protect yourself from injury.

Drilling into metal can cause tiny shards to fly off at high speeds. If one lodges itself in your eye, that will be a serious eye injury. Make sure you’re wearing appropriate eye protection before you start drilling; safety glasses that wrap around the sides of your face are the best option. Meanwhile, wear gloves and clothes without any hanging parts and keep long hair securely tied back.

6. Drill At a Low Speed

Now that everything is set up correctly, it’s time to start drilling!

Start at a slow rotation speed and only go faster if necessary. Stainless steel plate requires a slower drilling speed compared to other materials due to its hard composition. Using high speed can generate excessive heat, leading to work hardening of the metal, which makes drilling more challenging; while the lower speed can avoid damaging the drill bit and the stainless steel surface, thus producing a better result.

7. Use Lubricants

Stainless steel plate is pretty abrasive when you drill it. If you’re drilling it dry, the cutting edge will wear down extremely quickly. Therefore, lubrication is crucial when drilling. It helps reduce heat and friction, extending the life of the drill bit and improving drilling performance.

Remember to choose the lubricants specifically designed for stainless steel applications. These fluids often contain additives that enhance lubrication, reduce heat generation, and improve tool life.

8. Apply Enough Pressure

If you don’t apply enough pressure to the drill, the bit will rub instead of drilling, and disaster ensues. But too much pressure will cause the drill bit to glow red and will permanently damage the drill bit; at the same time, the stainless steel plate may turn black and go very hard which will make future drilling quite difficult.

So it’s important to maintain a steady and firm pressure on the drill. Apply consistent downward pressure, allowing the drill bit to cut through the stainless steel at a controlled pace. This helps maintain accuracy and prevents any mishaps during the drilling process.

9. Keep the Drill Straight

Drills aren’t meant for side pressure, and stainless steel plate is unforgiving.

Pay extra attention to how straight you’re drilling stainless steel plate. Otherwise, the shank of the drill will rub into the side of the hole, making it oblong; and you’re running a high risk of snapping the bit.

10. Stopping Drilling

After the hole is drilled, keep the drill speed constant and quickly remove the drill bit from the work surface. Do not make any skin contact with the equipment or the bit immediately after you drill the hole. You might end up burning your fingers.

11. Clean Up

The final step is to neaten and smooth any rough edges within the hole. You can use a specialist deburring tool for this, or you can use a metal file to remove the rough edges left around the holes. And then wipe off the excess lubricating oil and some stains that may have formed on the metal surface.

Note: for larger or deeper holes, it’s advisable to start with a pilot hole. A pilot hole provides a guide for the drill bit, ensuring more precise drilling and reducing the chances of the bit wandering off. Use a smaller drill bit than the final desired hole size and drill a shallow hole to create the pilot hole. Once the pilot hole is made, switch to the desired drill bit and continue drilling through the stainless steel plate.

Common Methods of Drilling Holes in Stainless Steel Plate

In the steel processing market, many methods exist to make holes in stainless steel plates. They are mainly divided into four types: manual drilling, electric drilling, hydraulic punching, and automatic drilling.

1. Manual Drilling: it is to use a manual wheel to complete the drilling. When the metal is fixed on the work surface, apply some lubricant and then turn the manual wheel counterclockwise to complete the drilling.

2. Electric Drilling: it is a power drill, an actual combination of manual and electric operation. When using this type, someone must hold the power drill’s handle in one hand and control the drilling speed.

3. Hydraulic Punching: hydraulic punching is a processing method that uses a punch or the liquid pressure in the pipe to separate the pipe wall material under the support of the liquid pressure in the pipe after the hydraulic bulging is completed.

4. Automatic Drilling: it uses the powerful pressure of the machine to punch holes. Generally speaking, this is what we call perforated stainless steel plates nowadays.

Conclusion

With those tips in mind, drilling stainless steel plates should not be an overwhelming task as many people think. As long as you know the processes, have the right tools, and drill accurately, you should be able to make holes through stainless steel sheets and plates with less hassle. What is important is to keep yourself safe by wearing protective gear like eye goggles, working gloves, and protective earbobs to minimize noise. With some patience and practice, you’ll soon be an expert at drilling stainless steel!