How To Prevent Stainless Steel Plate from Corrosion and Rust?

In previous blog posts, we introduce a blog post that focuses on the factors that cause corrosion of stainless steel plates: 11 Factors That Will Corrode Stainless Steel Plate. Today, let’s mainly talk about how to prevent the corrosion of stainless steel plates.

1. Using Alloys

Alloy addition is an effective method to improve the rust and corrosion resistance of stainless steel plates. By adding a certain proportion of alloying elements, such as chromium, nickel, etc., during fabrication, the corrosion resistance of stainless steel plates can be increased. The alloy elements will chemically react with the iron elements in the stainless steel plate to form a dense oxide film, which blocks the corrosion of stainless steel by external oxygen and moisture, thereby achieving the effect of preventing rust and corrosion.

Among those alloy elements, chromium plays a decisive role in preventing rust and corrosion of stainless steel plates. Generally speaking, the higher the chromium content, the greater the protection from rust and corrosion, and the higher the stainless steel grade. For example, 316 is more resistant than 304 stainless steel.

2. Correct Fabrication

During the fabrication stage, it is important to prevent stainless steel plates from contacting iron or ordinary steel. This requires vigilance in surveying the surrounding environment including work tables, tools, storage units, steel turning rolls, and chains. Any carbon steel dust particles settling onto the stainless steel plate during fabrication can contaminate its surface, increasing the potential for rust formation. Furthermore, cleaning and grinding tools that have been used with carbon or low alloy steel must be kept separate from stainless steel plates. Here are some necessary tips that should be taken carefully care of:

1. Keep stainless steel and carbon steel fabrication areas separate, which can reduce the risk of iron contamination. Iron particles can be embedded into the stainless steel plate and damage the oxide layer, thus producing localized or pitting corrosion at the site of contamination.

2. Avoid grinding of carbon steel near stainless steel. Grinding can embed carbon steel into the stainless steel plate, causing staining and localized corrosion.

3. Keep stainless steel and carbon steel inventories separate. This reduces the risk of iron contamination.

4. Steel bands are routinely used to secure fabricated parts to skids and other packaging used to transport. Place cardboard or other appropriate packaging material on top of stainless steel parts, and then wrap the steel bands on top of this packing material, preventing the carbon steel band from making direct contact with the stainless steel.

5. Use stainless steel processing and handling equipment when possible. Use work table bearers, non-metallic contact materials, and vacuum lifting equipment.

6. Do not allow your completed fabrications to ship untapped. Road salts contain high levels of chlorides — a chemical that can produce corrosion in stainless steel plates. Moreover, do not allow steel chains to come in contact with stainless steel.

3. Proper Storage

While storing stainless steel plates, it should be put in place where the area won’t be too damp; in other words, the area should not have any water or humidity nearby. The room you store things in must be dry to prevent corrosion from happening.

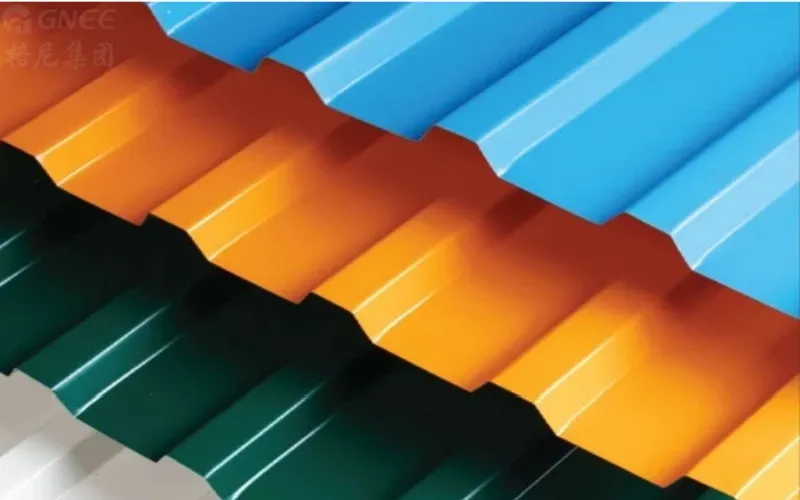

4. Applying Protective Coating

Equipping the stainless steel plate with a protective coating is one of the most effective ways to prevent uniform corrosion from occurring. The coating acts as a barrier between the steel and corroding agents such as rain, humidity, and salt. The lower the permeability of the coating system to water, the better the protection provided. It can be shown in the following two wet and dry methods:

Adding Oil/Lubricant: Adding oil or lubricant is also an essential way to maintain the upkeep of steel products that corrode. If stainless steel plate is left sitting out for an extended period, corrosion can occur from the moisture in the air. So, the oil acts as a barrier to prevent moisture from sitting for a long time, creating oxidation.

Applying Dry Coating: Since oil and lubricant are liquid, they cause items to become slippery and hard to hold. Instead, we can try applying a dry coating onto the stainless steel plate. It can be applied in the following four aspects:

1. Two-pack epoxy coatings and chlorinated rubbers applied at sufficiently high film build offer the most successful corrosion protection through barrier prevention. Common coating materials include polyester resin, epoxy resin, etc.

2. Paint and/or primers are a straightforward and cheap way to prevent corrosion, and may be necessary anyway for aesthetic reasons. However, since paint itself is susceptible to chipping and deterioration, it is important to re-apply it whenever wear occurs.

3. Powder coating can also create a protective layer of plastic material — epoxy, nylon, etc. — on the surface of the metal.

4. For some metals, it may be preferable to add hard chrome plating (affordable, good corrosion resistance) or black chrome plating (more expensive, excellent corrosion resistance).

5. Apply Sacrificial Coating — Galvanizing

Another way to make stainless steel plate corrosion-resistant is to apply a sacrificial coating. The purpose of a sacrificial coating is not to prevent corrosion altogether, but to allow the coating to get corroded rather than the underlying material of the part.

One typical example is zinc on metal parts. When we galvanize the stainless steel plate, we place a zinc coating on top of the steel surfacing. Not only does it corrode in preference to the steel, but the rate of corrosion is generally slower. This rate, however, is accelerated in the presence of ions such as chlorides in coastal locations.

6. Mechanical Protection

Mechanical treatment is a common method for stainless steel products to prevent rust and corrosion. Tools such as sandpaper, grinding wheels, or wire brushes are usually used to polish the surface of stainless steel to remove rust and dirt on the surface and restore the smoothness of the stainless steel surface. This method is more suitable for minor rust on the stainless steel surface and can effectively prevent the further spread of rust. But it is also time-consuming and laborious.

7. Chemical Protection

Common chemical treatment methods include pickling, electrochemical treatment, and passivation treatment.

1. Pickling uses an acidic solution to treat the surface of the stainless steel plate to remove iron oxide scale and rust on the surface and restore the brightness of the stainless steel.

2. Electrochemical treatment uses electrolysis to form a protective film on the surface of stainless steel to prevent further corrosion.

3. Passivation treatment uses acidic solutions or oxidants to form a dense oxide film on the surface of stainless steel to enhance the corrosion resistance of stainless steel.

8. Regular Maintenance

Regular maintenance plays a key role in stainless steel plate rust prevention as well as limiting the progression of existing rust.

It is essential to remove any rust that has formed using mechanical or chemical means. The resulting grime can then be cleared away using warm water and soap. After cleaning, a rust-resistant coating should be applied.

9. Environment Consideration

No matter what kind of metal product it is, keeping it in a dry environment is the most important thing. I know this is easier said than done, especially in certain industrial and construction applications, but stainless steel needs to remain dry. Rust and corrosion occur when metals are exposed to moisture over a prolonged length of time. It doesn’t happen overnight — not usually, at least — but constant exposure to moisture can and will cause rust. The moisture particles will settle into the metal, producing new chemical changes known as oxidation. These chemical changes can in turn cause the formation of rust and corrosion.

Besides, in certain situations, it may be possible to control the amounts of substances like salt or chlorine in the surrounding environment. Those substances can accelerate the speed of corroding stainless steel plate products.

Find Anti-Rust Solutions For Your Stainless Steel at Gnee Steel

In this part, we learn many useful methods about how to prevent stainless steel plates from corroding. However, the choice of precaution measurement should be determined according to different use environments, projects, and requirements. When it comes to building with satisfaction and creative freedom while also following the best practices of delivering quality, Gnee Steel can provide what you need. Contact us here for more information on how we can help create the best stainless steel products that resist corrosion and rust.